Apple to Start Mass Producing Self-Designed Mac SoC, Projected to Cost under US$100, in 1H21, Says TrendForce

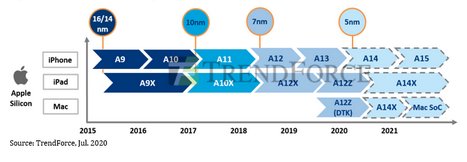

July 7, 2020 -- According to the latest investigations by TrendForce, Apple officially unveiled its self-designed Mac SoC processors based on the ARM architecture in June, with the market release of the first Mac device with Apple Silicon (which broadly refers to chips designed by Apple) scheduled to take place by the end of this year. The first Mac SoC, projected to cost under US$100, will be mass produced with TSMC’s 5nm process technology. The low cost of the Mac SoC makes it an extremely cost-competitive option.

According to TrendForce, Apple’s current plan for its wafer input at TSMC indicates that the foundry will still be mainly producing chips for iPhone and iPad devices in 2020. Mass production of the A14 Bionic SoC for the new iPhone devices that will be released later this year is now underway, while production of the A14X Bionic SoC for the new iPad devices that will be released in 2021 is scheduled to begin in small volumes in 3Q20. TrendForce expects wafer input for Mac SoC to begin in 1H21, meaning the actual adoption of Mac products featuring the latest Mac SoCs is expected to occur in 2H21.

With adoption of 5nm process technology, Apple Silicon takes on Intel’s mainstream CPUs in the battle for performance

Initially, ARM-based SoCs were able to become mainstream in the smartphone market because of their unique advantage in power consumption. However, the ARM family of processor architectures as a whole has also made huge leaps in computing performance in the recent years. It is now sufficiently strong in both computing speed and power efficiency to have opportunities to challenge the Intel family in the high-performance computing segment. As well, TSMC is one to two generations ahead of Intel with respect to process shrink. TSMC’s technological lead in the market could be an additional reason as to why Apple has now decided to begin phasing out Intel CPUs from Mac devices. Nevertheless, the most crucial factors that drive Apple’s decision are the cost consideration and the desire to further build out its ecosystem. Although Apple still needs TSMC to manufacture its self-designed processors, the production cost of a Mac processor made with TSMC’s 5nm node is currently estimated under US$100, which is considerably more cost-effective compared to the 10nm Intel Core i3 processors, priced around US$200 to US$300 on the market.

On the other hand, Intel’s CPUs scheduled to be released in 2021 will still be based on the 10nm node. With Apple Silicon advancing to the 5nm node, the future Mac SoCs will be packed with a lot more transistors while maintaining the same chip size thanks to process shrink. They thus will have a chance to successfully compete against the mainstream products offered by Intel in terms of computing performance and power consumption.

Related Semiconductor IP

- HiFi iQ DSP

- CXL 4 Verification IP

- JESD204E Controller IP

- eUSB2V2.0 Controller + PHY IP

- I/O Library with LVDS in SkyWater 90nm

Related News

- proteanTecs and Teradyne Partner to Bring Machine Learning-driven Telemetry to SoC Testing

- CAST Adds Ethernet MAC, 64-Bit PCI, and CAN Controller to Line of General Purpose IP Cores

- Magis demos synchronous MAC with 802.11a radio

- inSilicon and Mysticom's Popular 10/100-Mbps Ethernet MAC and PHY Technologies Proven in Rigorous Interoperability Testing

Latest News

- Victor Peng Joins Rambus Board of Directors

- Arteris Announces Financial Results for the Fourth Quarter and Full Year 2025 and Estimated First Quarter and Full Year 2026 Guidance

- Arteris Network-on-Chip Technology Achieves Deployment Milestone of 4 Billion Chips and Chiplets

- RISC-V Pivots from Academia to Industrial Heavyweight

- Arteris Technology Deployed More Broadly by NXP to Accelerate Edge AI Leadership