Silicon-proven LVTS for 2nm: a new era of accuracy and integration in thermal monitoring

Effective thermal management is crucial to prevent overheating and optimize performance in modern SoCs. Inadequate temperature control due to inaccurate thermal sensing compromises power management, reliability, processing speed, and lifespan, leading to issues like electromigration, and hot carrier injection and even thermal runaway.

Unfortunately, precise thermal monitoring reached an inflection point at 2nm, with traditional solutions proving less practical below 3nm. To tackle the issue, this article delves into a novel approach, accurate to ±1.0°C, that overcomes this critical challenge.

proteanTecs now offers a customer-ready, silicon-proven solution for 5nm, 3nm and 2nm nodes. In fact, our latest silicon reports demonstrate robust performance, validating that accurate and scalable thermal sensing is achievable in the most advanced nodes.

Accurate Thermal Sensing in Advanced Process Nodes: A Growing Challenge

As process nodes scale to 2nm and below, accurately measuring on-chip temperature has become increasingly difficult. Traditional Voltage and Temperature sensors based on diodes are less practical in these nodes due to their high-voltage requirements. This gap in temperature measurement creates risks that compel chipmakers to seek future-ready solutions. The challenge is magnified in designs that leverage DVFS techniques.

Why Traditional Solutions Fall Short

Traditional thermal sensing technologies are hitting hard limitations in precision and overall feasibility when moving beyond 3nm:

- Temperature sensors based on BJT diodes

Analog thermal diodes with Bipolar Junction Transistors (BJTs) have been a go-to option for accurate thermal sensing. However, their reliance on high I/O voltages makes them inapplicable for nodes beyond 3nm based on Gate-All-Around (GAA) technology, which doesn't support high I/O (analog) voltages, and BJT support may be discontinued as well in the future.

PNPBJT in a diode-connected configuration. The base-emitter junction has a predictable transfer function that depends on temperature, making it suitable for thermal sensing. However, analog thermal diodes are a no-go for nodes beyond 3nm.

Even before GAA, thermal diodes suffered from low coverage as they were hard to integrate. Their design restricted placement to chip edges near the I/O power supply, leaving vital internal areas unmonitored due to analog routing limitations. Furthermore, they consumed more power than low-voltage alternatives due to their high-voltage requirement.

- Digital Temperature Measurements based on Ring oscillators

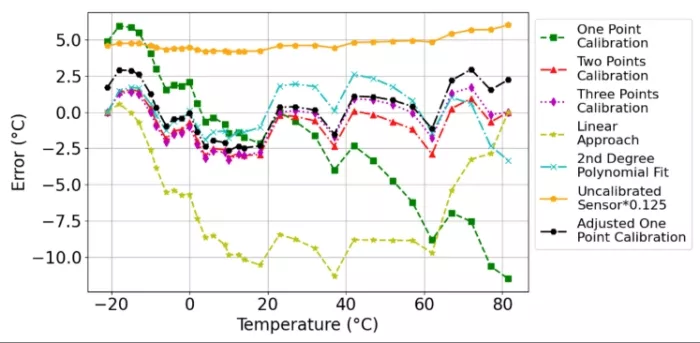

Ring oscillators are scalable to advanced nodes, but their temperature measurement error can be as high as ±10°C. They are inadequate where accuracy is paramount. One example concern using thermal sensing to determine voltage or frequency adjustments (e.g. DVFS), as even slight temperature variations can significantly degrade performance.

Ring oscillator temperature error of different calibration techniques. Can be greater than -10°C, which is too high for many use cases.

The limitations above underscore the need for an accurate thermal sensing solution designed with core transistors only to fit advanced nodes.

A Thermal Sensor Built for the Future

proteanTecs LVTS™ (Local Voltage and Thermal Sensor) is purpose-built for precision thermal sensing in advanced nodes without relying on I/O transistors and high analog I/O voltages and even BJTs. It measures temperature with accuracy of ±1.0°C while using core transistors exclusively and operating in a wide range of core voltages, combining precision with future readiness for GAA nodes.

Key features of LVTS:

- Temperature measurement accuracy of +/-1°C (3-sigma)

- Voltage measurement accuracy of +/-1.5% (3-sigma)

- Over temperature fast alert

- Wide range of operational voltages (650-950 mV)

- High-speed measurement

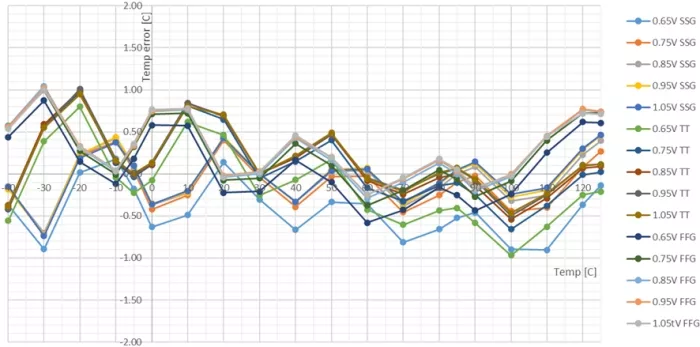

proteanTecs LVTS measurements demonstrate an accuracy of ±1°C in a wide range of voltages (0.65V SSG – 1.05V FFG) and temperatures (-40°C - 125°C.)

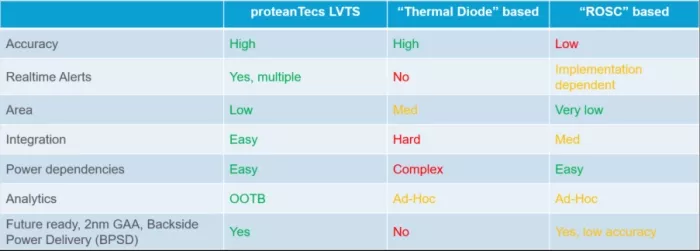

Unmatched Benefits Across All Critical Parameters

LVTS operates with low VDD core rather than high I/O voltage while maintaining superb accuracy, unlike Digital Thermal sensors based on ring oscillators. This unique design enables easy integration anywhere on the chip, providing more granular voltage and temperature monitoring than thermal diodes. Additionally, its smaller size and lower power consumption minimize the impact on PPA compared to BJT-based solutions.

LVTS compared with thermal diodes and ring oscillators (ROSC)

An additional capability of LVTS provides real-time warnings and critical alerts in the form of HW signals when predetermined thermal thresholds are breached. This feature enables immediate corrective action, reducing the risk of overheating to maintain chip integrity.

LVTS Flavors for Enhanced Flexibility

In addition to the standard LVTS described above, proteanTecs offers two specialized variants to address diverse design needs:

- An extended flavor - includes external voltage measurement to extend the measured voltage range down to zero volts.

- A distributed flavor - designed as a Core VDD-only, analog thermal and DC voltage level sensor hub, it supports extremely small remote thermal sensors for precise temperature measurements at hot spots.

These two versions complement the regular LVTS, allowing chipmakers to tailor their thermal sensing approach for maximum coverage, precision, and responsiveness in critical areas of the design.

Complementing Deep Data Analytics with Accurate Voltage and Temperature Sensing

LVTS is already silicon-proven in 5nm, 3nm, and now also in 2nm, with a detailed silicon report available, making it the industry-leading, future-proof, customer-ready solution.

This innovation was warmly embraced by multiple chipmakers concerned about the absence of accurate and reliable thermal sensing in next-generation silicon.

These customers use LVTS alongside other proteanTecs products, as it complements the broader deep data monitoring and analytics solutions explored here.

LVTS is seamlessly integrated into proteanTecs’ HW Monitoring System, enabling accurate DC voltage and thermal measurements real-time, making LVTS a vital addition to chipmaker power and reliability strategies.

Want to know more about how LVTS can help scale your design to advanced nodes with accurate voltage and temperature sensing? Contact us here.

Related Semiconductor IP

- Process/Voltage/Temperature Sensor with Self-calibration (Supply voltage 1.2V) - TSMC 3nm N3P

- Ultra-low power high dynamic range image sensor

- PSI5 IP Core Controller for Peripheral Sensor Interface 5 Communication

- AI processing engine - Voice control, Context detection and Sensor applications

- PVT Sensor Subsystem

Related Blogs

- SiFive; Empowering A New Era of Data Center Innovation

- Analog Bits Steals the Show with Working IP on TSMC 3nm and 2nm and a New Design Strategy

- LPDDR6: A New Standard and Memory Choice for AI Data Center Applications

- UEC-LLR: The Future of Loss Recovery in Ethernet for AI and HPC

Latest Blogs

- Silicon Insurance: Why eFPGA is Cheaper Than a Respin

- One Bit Error is Not Like Another: Understanding Failure Mechanisms in NVM

- Introducing CoreCollective for the next era of open collaboration for the Arm software ecosystem

- Integrating eFPGA for Hybrid Signal Processing Architectures

- eUSB2V2: Trends and Innovations Shaping the Future of Embedded Connectivity