Agile Design for Hardware, Part II

David Patterson and Borivoje NikoliÄ, UC Berkeley

EETimes (7/30/2015 07:00 AM EDT)

In the second of a three-part series, two Berkeley professors suggest its time to apply Agile design techniques to hardware.

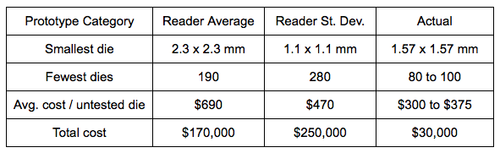

We asked readers of Part I to guess the cost of a prototype run of 28 nm chips, as Agile development relies on a sequence of interim prototypes versus the One Big Tapeout of the traditional Waterfall process. Here are the results:

The surprisingly low manufacturing cost of prototype chips—one fifth the readers’ estimate—means Agile development is eminently affordable, even for academics. (See www.AgileSoC.com for more evidence.) It also calls into question the current high cost of designing SoCs using the Waterfall process. Having established Agile’s viability, based on our experience we propose four guidelines to lower development costs.

To read the full article, click here

Related Semiconductor IP

- JESD204E Controller IP

- eUSB2V2.0 Controller + PHY IP

- I/O Library with LVDS in SkyWater 90nm

- 50G PON LDPC Encoder/Decoder

- UALink Controller

Related Articles

- Agile Design for Hardware, Part I

- How to design secure SoCs, Part II: Key Management

- QiMeng: Fully Automated Hardware and Software Design for Processor Chip

- How to design secure SoCs, Part III: Secure Boot

Latest Articles

- Crypto-RV: High-Efficiency FPGA-Based RISC-V Cryptographic Co-Processor for IoT Security

- In-Pipeline Integration of Digital In-Memory-Computing into RISC-V Vector Architecture to Accelerate Deep Learning

- QMC: Efficient SLM Edge Inference via Outlier-Aware Quantization and Emergent Memories Co-Design

- ChipBench: A Next-Step Benchmark for Evaluating LLM Performance in AI-Aided Chip Design

- COVERT: Trojan Detection in COTS Hardware via Statistical Activation of Microarchitectural Events