Thalia enhances AMALIA Platform with new AI models to revolutionize analog, RF and mixed-signal IC design migration

Cwmbran, United Kingdom – April 29, 2025 – Thalia, a cutting-edge semiconductor solutions provider, unveils the latest version of its AI-powered AMALIA Platform, offering advanced end-to-end IP reuse capabilities specially designed for semiconductor companies and silicon foundries.

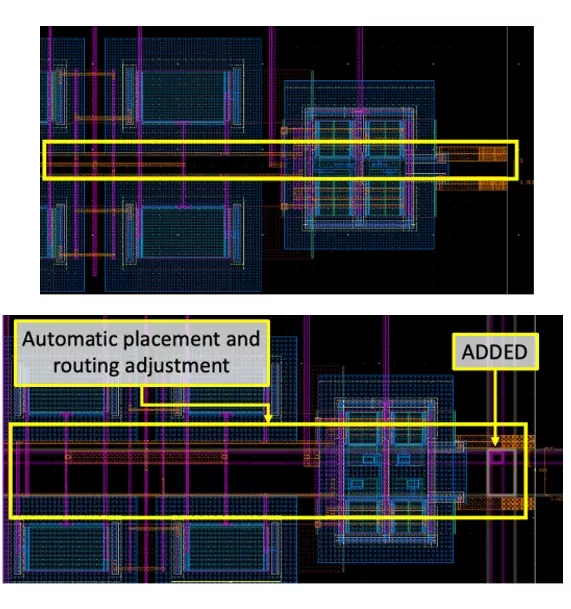

The new release introduces significant enhancements to the automated device-stretching functionality within the Layout Automation Suite of AMALIA. Noteworthy additions to the platform include substantial improvements to inductor characterization and accurate area estimation models, underscoring Thalia’s commitment to driving efficiency and reducing design migration time.

Awadh Pandey, Thalia’s Director of Engineering, highlighted the innovation behind these updates, stating, “Our engineers’ deep expertise in analog and RF IC design, combined with AI modeling proficiency, has enabled us to deliver time-saving user interactions in physical layout design. The refined inductor characterization and area estimation features will significantly cut down both time and costs associated with the IC design migration process.”

Figure – Illustration of automatic device stretching. Creating space, layers/metal/shapes automatically adjusted

New features in release version 25.1

- Layout Automation Suite enhancements: Automatic device stretching, DRC detection and correction, and metal stacking features streamline layout optimization, ensuring compliance with design rules and enhancing connectivity.

- Inductor characterization improvement: For RF applications like Wi-Fi and Bluetooth devices, the updated inductor characterization feature offers automated analysis based on PDK data, enhancing efficiency and accuracy for designers.

- Enhanced area estimation model: Integrated into the Circuit Porting Suite, the updated model provides precise area estimates, enabling customers to optimize space utilization and improve design performance.

Customer benefits include

- Increased efficiency: Automation reduces manual effort, saving time for critical project aspects.

- Enhanced accuracy: Automatic error detection and correction ensure adherence to design rules, improving product quality.

- Cost savings: Efficient space use minimizes manufacturing costs and post-production revisions.

- Customer satisfaction: Tailored features address specific design challenges, providing a competitive edge in the market.

Related Semiconductor IP

- 5G-NTN Modem IP for Satellite User Terminals

- 14-bit 12.5MSPS SAR ADC - Tower 65nm

- 5G-Advanced Modem IP for Edge and IoT Applications

- TSN Ethernet Endpoint Controller 10Gbps

- 13ns High-Speed Comparator with no Hysteresis

Related News

- Thalia's AMALIA (23.4a) qualified on Siemens AFS for increased analog design migration flexibility

- Siemens delivers AI- accelerated verification for analog, mixed-signal, RF, memory, library IP and 3D IC designs in Solido Simulation Suite

- Thalia Design Automation launches AMALIA Platform 25.2

- Thalia Design Automation announces AMALIA Platform release 25.3 qualified for advanced process nodes down to 4nm

Latest News

- Altera Advances FPGA-Based Physical AI for Robotics and Edge Applications

- TES offers new High-Speed Comparator IPs for X-FAB XT018 - 0.18µm BCD-on-SOI technology.

- QuickLogic Reports Fiscal Fourth Quarter and Full Year 2025 Financial Results

- MIPS, GlobalFoundries Bet on Physical AI

- IPrium releases LunaNet AFS LDPC Encoder and Decoder for Lunar Navigation Satellite Systems