7纳米以下IC工艺需求增长,单片晶圆收入与日俱增

Despite high development costs, using smaller nodes yield larger revenue per wafer.

February 20, 2020 -- The success and proliferation of integrated circuits has largely hinged on the ability of IC manufacturers to continue offering more performance and functionality for the money. Driving down the cost of ICs (on a per-function or per-performance basis) is inescapably tied to a growing arsenal of technologies and wafer-fab manufacturing disciplines as mainstream CMOS processes reach their theoretical, practical, and economic limits.

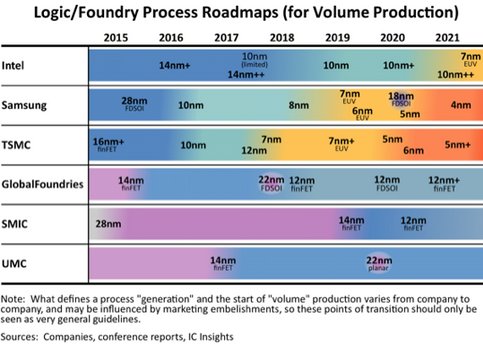

Based on data presented in IC Insights’ new edition of The McClean Report (released in January 2020), many IC companies are now designing high-performance microprocessors, application processors, and other advanced logic devices based on 10nm and 7nm process technology. Some of the current iterations from logic and foundry suppliers are shown in Figure 1.

Figure 1

With more variety than ever among the processes that companies offer, it is challenging to compare them in a fair and useful way. Moreover, “plus” or derivative versions of each process generation and half steps between major nodes have become regular occurrences.

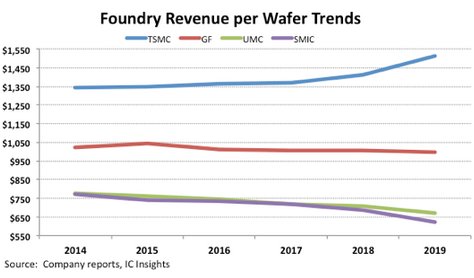

In the foundry world, manufacturing with leading-edge processes carries a distinct advantage. In 2019, TSMC was the only pure-play foundry manufacturing ICs using 7nm process technology. Not coincidentally, its overall revenue per wafer increased significantly as leading fabless IC suppliers lined up to have their newest designs manufactured on the 7nm process. TSMC was the only pure-play foundry that enjoyed higher revenue-per-wafer in 2019 (13%) compared to 2014. In contrast, 2019 revenue per wafer figures at GlobalFoundries, UMC, and SMIC—whose smallest process node is 12/14nm—were down by 2%, 14%, and 19% respectively, compared with 2014.

Figure 2

Besides foundry and logic IC manufacturing, memory suppliers like Samsung, Micron, SK Hynix, and Kioxia/WD are using advanced processes to make their DRAM and flash memory components. No matter the device type, the IC industry has evolved to the point where only a very small group of companies can develop leading-edge process technologies and fabricate leading edge ICs. Growing design and manufacturing challenges and costs have divided the integrated circuit world into the haves and have-nots. Marketshare makeup in various IC product segments has become “top heavy,” with increasing shares held by the top producers, leaving very little room for remaining competitors.

Report Details: The 2020 McClean Report

Additional details on other IC technology and market trends within the IC industry are provided in The McClean Report—A Complete Analysis and Forecast of the Integrated Circuit Industry (released in January 2020). A subscription to The McClean Report includes free monthly updates from March through November (including a 200+ page Mid-Year Update), and free access to subscriber-only webinars throughout the year. An individual-user license to the 2020 edition of The McClean Report is priced at $4,990 and includes an Internet access password. A multi-user worldwide corporate license is available for $7,990.

Related Semiconductor IP

- Multi-channel Ultra Ethernet TSS Transform Engine

- Configurable CPU tailored precisely to your needs

- Ultra high-performance low-power ADC

- HiFi iQ DSP

- CXL 4 Verification IP

Related News

- 迎合5nm / 7nm IC工艺与日俱增的需求,每片晶圆的营收也节节攀升

- 台湾赶超韩国成为最大IC晶圆产能基地

- 台湾独占鳌头,保持全球最大半导体晶圆生产基地

- 据集邦咨询最新数据:季节性消费与AI热潮延续,推升全球十大IC设计公司第三季营收环比增长17.8%